SMED

SMED, an abbreviation for "Single Minute Exchange of Dies" is a lean methodology that is used to reduce the changeover (setup) time of machines and equipment.

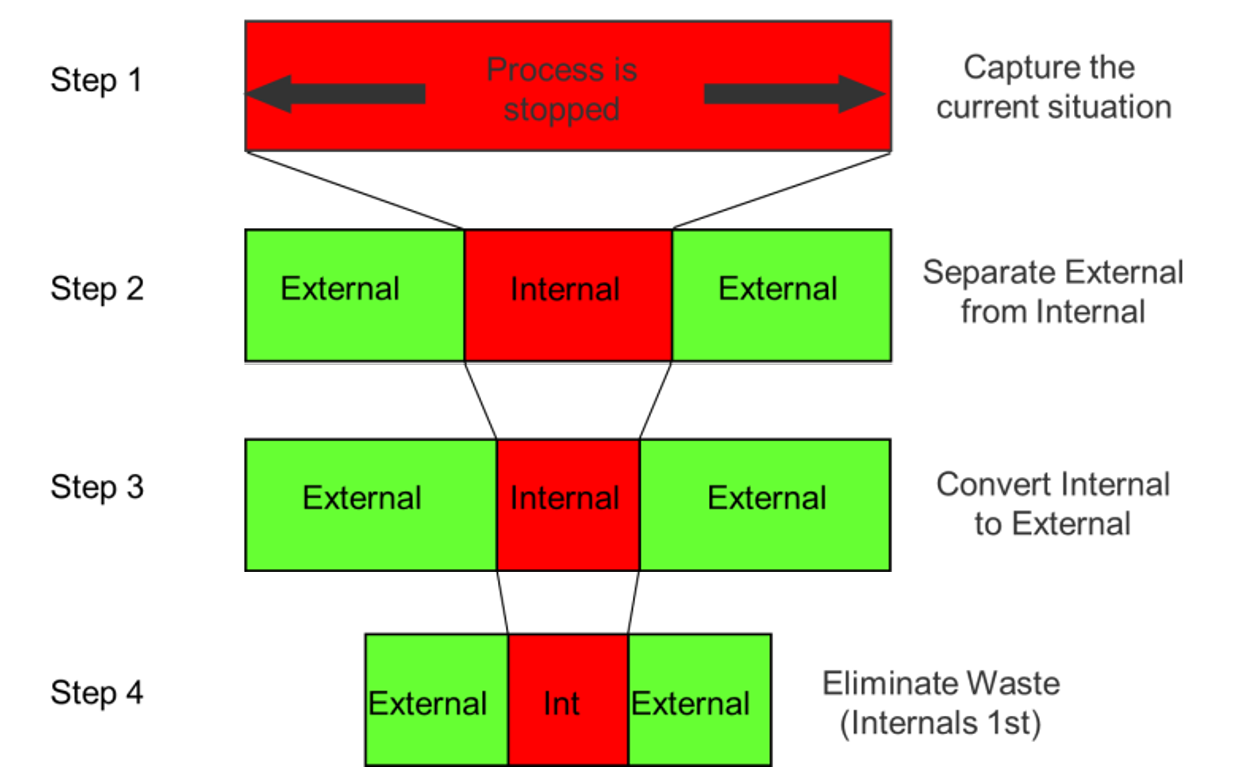

This is achieved by making adjustments so that as many of the setup tasks as possible can be carried out externally (i.e. while the machine / process is running) and then eliminating sources of waste associated with the remaining internal setup tasks.

Lower setup times allow for smaller production runs, increased machine availability, shorter lead times and an overall competitive advantage for the business.