OEE & OLE

OEE (Overall Equipment Effectiveness) for equipment and OLE (Overall Labour Effectiveness) for manual processes are measures of manufacturing productivity. They are excellent ways of identifying losses and benchmarking improvements.

OEE and OLE are improvement initiatives that are most effective when applied at our 'bottleneck' processes that pace production.

The calculation is:

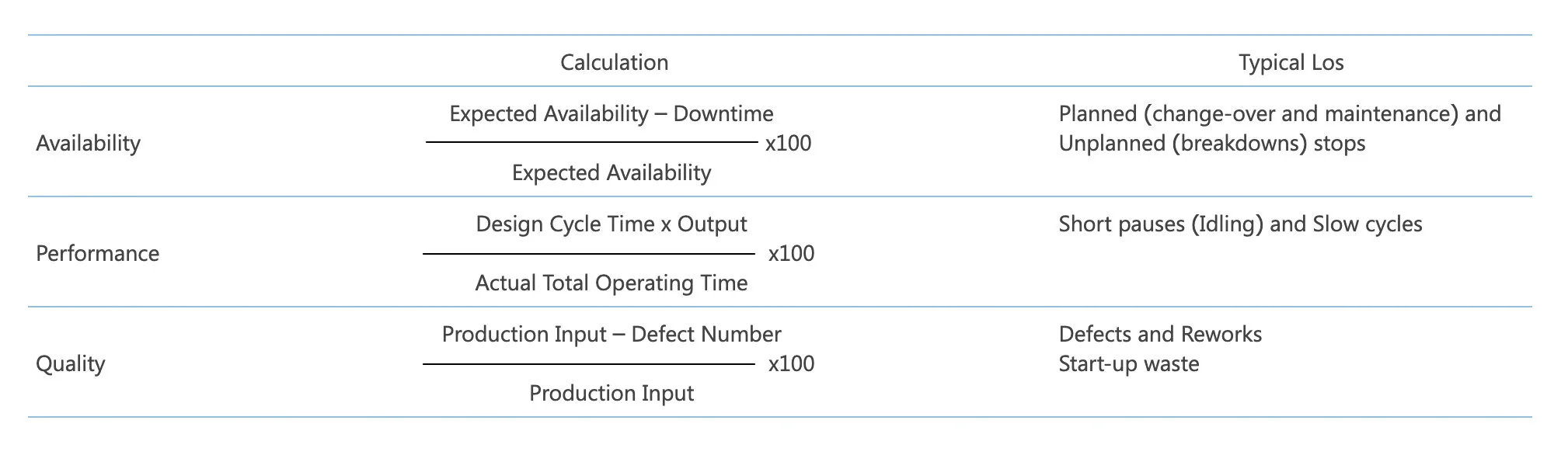

OEE or OLE (%) = Availability (%) x Performance (%) x Quality (%)

OEE/OLE improves when we eliminate the underlying losses within our process. Lost Time Analysis (LTA) focusses on these losses and the necessary actions to reduce them, which in turn will naturally improve OEE/OLE.

TEEP (Total Effective Equipment Productivity) can also be used to measure performance versus the theoretical maximum capacity. It is measured over 24hrs/7days a week, which unlike OEE/OLE, includes scheduled losses (plant not open/no production scheduled).

When applied correctly, OEE/OLE measures the performance of a manufacturing process against the theory of perfect performance (no losses in downtime, always running at designed cycle time and no scrap or quality issues).